The Mark IV Industrial TrimMaster brake from Van Mark, featuring new POWERslot hinge technology, provides single user setup and operation in the shop and on the job site. Non-marring vinyl strips protect clad and painted finishes leaving clean crisp bend lines and hems. The unique cam-locking system clamps tightly to any thickness of material as opposed to a single factory preset thickness. Should you ever need to fine-tune your brake, each casting comes with independently adjustable UHMW wedges. While some brake manufacturers have taken away your ability to make these adjustments, its nice to know the TrimMaster gives you the choice, even if you never have to use it.

The included "Xtreme" Stand installs in seconds, won't loosen or rattle under any work load, and provides a secure standing platform to counter-weight the brake, eliminating the chance of tipping when working with heavy gauge metals!

The Mark IV Industrial works perfectly with the 3017 Trim Cutter for quick, clean material cutting directly on the brake.

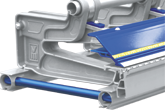

Van Mark's unique cam-locking system locks tightly to any thickness of material, every time, completely eliminating the need to adjust your clamping pressure from one job or material to the next. The FTA system (Fine-Tune Adjustment) provides the capability of adjusting the locking tension of the brake through use of the UHMW wedges between the locking cams and C-castings.

The hollow-core fixed hinge, bending hinge and base rail design feature reinforced walls and hollows, making this and incredibly strong and durable brake.

At a Glance:

- The Mark IV Industrial Brake has the strongest bending capacities you can find of any portable brake in the industry.

- The heavy-duty, extruded aluminum shop stand is included with every Mark IV brake. The Xtreme Stand will not rock, rattle, roll or rust. Unit is fully detachable in seconds and collapsible for easy, fast setup and transport.

- Full-loop locking and bending handles facilitate single operator use, and apply even bending pressure across the entire length of the brake, regardless of operator position.

- Heavy-duty hinge provides years of dependable service without risk of material curling at the ends or sagging in the center.

- Power Lock Bar provides stronger clamping pressure along the entire bending edge for crisp, clean bends without oil canning, or warping.

- Increased bending radius simplifies hemming and over-bending resulting in faster, easier operations, great for the metal roofing/building industry.

- Powder-Coat finish provides superior protection from the elements, while eliminating UV fading and oxidation.

|

Models

|

Bending Capacities

|

||||||

|

Model

|

Length

|

Cast's

|

Lbs/Kg

|

|

|

||

|

Aluminum (3003H14)

|

.050

|

||||||

|

IT6

|

6'6" (2.0m)

|

7

|

144 (65.3kg)

|

Galvanized Steel

|

20 ga.

|

||

|

IT8

|

8'6" (2.6m)

|

9

|

180 (81.6kg)

|

Painted Steel Grade D

|

24 ga.

|

||

|

IT10

|

10'6" (3.2m)

|

11

|

208 (94.3kg)

|

Roofing Copper

|

36 oz

|

||

|

IT12*

|

12'6" (3.8m)

|

13

|

247 (112kg)

|

Zinc Alloy

|

.050

|

||

|

IT14*

|

14'6" (4.4m)

|

15

|

287 (130.2kg)

|

Stainless Steel (304L)

|

24 ga.

|

||

| * Includes dual bending and locking handles | |||||||

Parts Diagram:

Van Mark Parts Diagram - Mark IV Industrial Brake

Shipping Information:

![]() Click Here for Freight Details

Click Here for Freight Details

FREE SHIPPING to COMMERCIAL ADDRESSES* within the lower 48 United States!

Fast, free freight delivery! Our Michigan warehouse is strategically located to deliver the tools and equipment you need as fast as possible. Are you just now ordering the tools you needed yesterday? We've got you covered. Call today!

866-588-6300 - Sales@MagnumTools.com

Canadian Customers - Take advantage of our Export Experts!!!

We've streamlined the process of exporting the American tools and equipment you want... Contact us direct for an all-inclusive quote! We eliminate the hassles of importing! Customs clearance, brokerage, NAFTA Documents, Taxes... One price, no surprises. Call today!

866-588-6300 - Sales@MagnumTools.com